Perfomance Center

Ultimate performance recording.

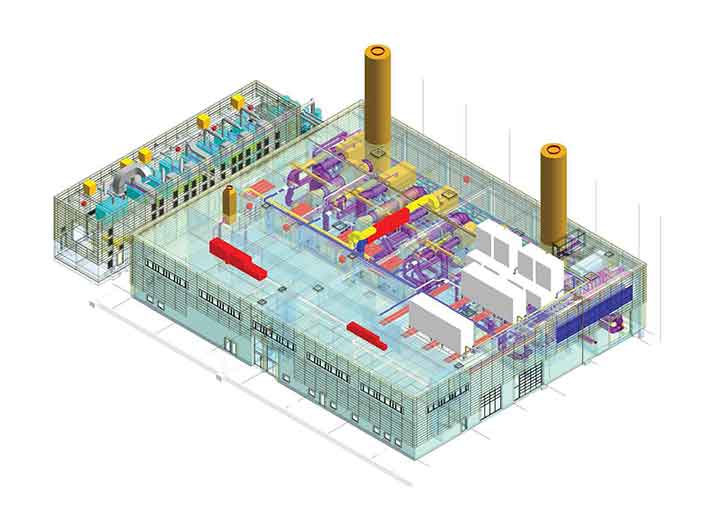

Our cutting-edge PBST Performance Center enables manufacturers of turbomachinery, turbochargers or other thermal machines to put

their equipment through the most rigorous tests. Our equipment will deliver clear and accurate measurement results. And it goes without saying, that protection of our customers' sensitive data is guaranteed at all times.

Performance recordings for you

Are you looking for a way to optimize your equipment via detailed performance recording? We are

standing by to test your entire turbocharger, turbine or other thermal machine in our cutting-edge

Performance Center.

Five burners and two component test rigs are available to be used in your tests. You

can either perform a test by yourself or with the support of our experienced staff. No matter what you

choose, we guarantee full confidentiality and data security.

Facts

- 5x TC test beds for different applications

- 2x component test rigs

- Available floor space: 5,250 m2

- Media building: approx. 800 m2

- Comprehensive test recording system

- Measurements performed by experts with calibrated

measurement devices - Profitability verification

- All tests are performed according to applicable

- rules and regulations

- Protected by NDA, full confidentiality and data

security standards

| TC test bed 1 | TC test bed 2 | TC test bed 3 | TC test bed 4 | TC test bed 5 | Turbine test rig (radial / axial) | |

|---|---|---|---|---|---|---|

| Mass flow [kg/s] | 0.8 – 20 | 2.0 – 50 | 0.1 – 70 | 0.2 – 6.0 | 0.1 – 3.0 | 3.00.8 – 20 |

| Pressure range [bar] | 12 | 12 | 7 | 12 | 7 | 12 |

| Power output [kW] | 12,500 | 32,000 | 45,000 | 3,600 | 1,700 | 12,500 |

| Max. temp. turbine inlet [°C] | up to 800 | up to 800 | up to 800 | up to 800 | up to 800 | up to 800 |

| Test bed type | 1- & 2-stage | 1- & 2-stage | 1-stage | 1- & 2-stage | 1-stage | component |

| Area per test bed [m2] | ~ 97 | ~ 108 | ~ 120 | ~ 65 | ~ 34 | ~ 98 |

| Crane capability [t] | 10 | 20 | 20 | 3.2 | 1 | 5 |

| Air supply | up to 17 kg/s air supply at 11.5 bar available for tests | |||||

State-of-the-art technology

Our new PBST Performance Center is equipped with the latest technology to enable our partners to

perform many series of test runs. Our qualified and experienced staff can offer consultations and support your test run if requested.

| Generated force | Max. acceleration | Max. shock force | Max. load | Free table moment | Max. frequency | ||

|---|---|---|---|---|---|---|---|

| Shaker test rig (hot / cold ) | 35.6 kN | 160 g peak | 80 kN | 3,000 kg | 1,524 x 1,524 mm | 900 Hz | 2,000 Hz |

Performance Center highlights

- Mass flow [kg/s] up to 70

- Turbine inlet temp. [°C]: < 800

- Noise according to ISO 3744 regulation

- Two slots are available for pre-assembly

- Containment test for full range of equipment

- Compliant with local emission regulations

Example types of equipment that can be tested:

- Turbochargers

- Gas turbines (shaft power, aircraft & stationary)

- Compressors

- Hot gas expanders

- Turbo-pumps

Want to know more?

Guided tours as well as individual project discussions are possible at any time. Please contact us to arrange a mutually convenient appointment. We are ready to meet your expectations – get in touch with us at air-management@pbst.eu